I'd hoped to put a Soundtraxx decoder in this locomotive. The biggest problem was access -- the decoder and speaker had to fit in the Vanderbilt tender, but the tender was soldered shut. I created access by unsoldering a sheet covering the top of the oil tank and cutting an access hole in the top of the oil tank structure. I could then maneuver a Soundtraxx decoder into the water tank portion of the tender, and place a speaker in the oil tender.

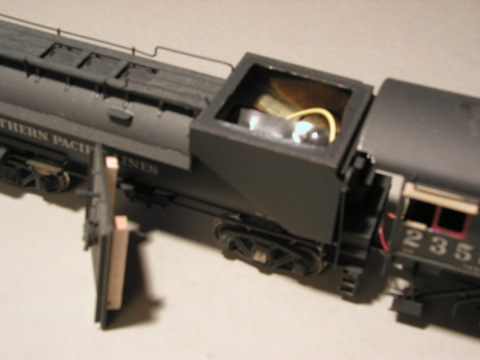

The top of the oil tank is removable to reach the DCC decoder.

The actual details of cutting open the tender was pretty low tech -- I pointed a pistol-type soldering iron at the top of the oil tank and kept heating it til the solder melted and the top let go. I cut the access hole with a dremel; if I remember correctly, I used a drill to put holes along the edges of the cut, and finished off with a cutoff wheel. The original oil tank top had stripwood strips added so it could be placed back on the top of the oil tank.

I never figured out a good way to get the sound out of the tender, and eventually gave up on sound. The locomotive currently has a Lenz LE130XF back-EMF decoder powering a can motor.

Four wires run between the locomotive and tender: two for the motor, one for the headlight, and one for track power. I use a Circuitron 4 pin connector for the locomotive-tender connection.

My primary modifications for this locomotive was to repaint it and replace the headlight and tender backup light so both could be illuminated. The tender light was the most interesting -- the back of the tender was soldered shut. When I replaced the old headlight, I also drilled holes so its wires could be routed through the tender deck, then through a hole at the bottom of the tank. The light's wire then ran inside the underframe (which was detachable), then back into the front of the tank to reach the DCC decoder. I only needed to route one wire -- all my headlights are 12 volt bulbs, with one wire connected to a DCC decoder's function output and the other to one track (or, in the case of this locomotive, straight to the body of the tender.) This approach keeps the voltage on the bulb low. There's also one less wire to route.